Precision Across Every Surface. Reliability Across Every Sector.

CRQ Technology delivers high-precision diamond tooling solutions to a diverse range of industries, including—but not limited to—aerospace, medical, energy, electronics, composites, ceramics, rubber, automotive, stone, and plastics. Our tools are engineered for accuracy and durability, helping manufacturers meet strict tolerances, reduce downtime, and boost productivity. Whether it’s machining turbine components, surgical instruments, semiconductors, or industrial parts, CRQ tools deliver consistent performance in the most demanding environments.

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

Industry Applications

Aerospace & Defense

CRQ tools are engineered to machine aerospace-grade materials like titanium, Inconel, and carbon composites used in turbine blades, airframes, and engine components. Our diamond tools ensure the highest levels of surface integrity, dimensional accuracy, and repeatability.

Medical & Dental Devices

Used in the manufacture of surgical instruments, implants, and dental devices, our tools offer exceptional results on stainless steel, zirconia, and ceramics—ensuring biocompatibility and exacting finish standards with every application.

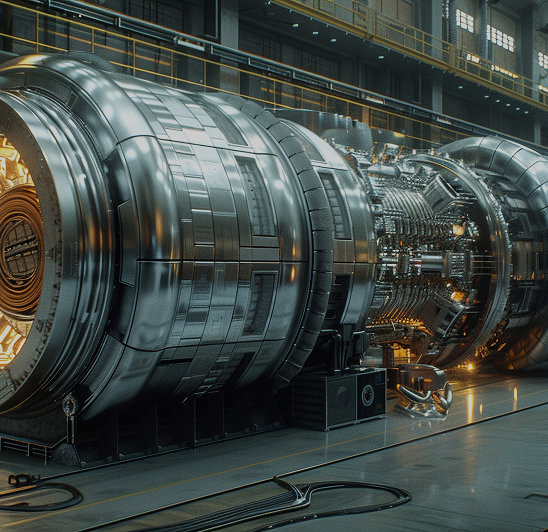

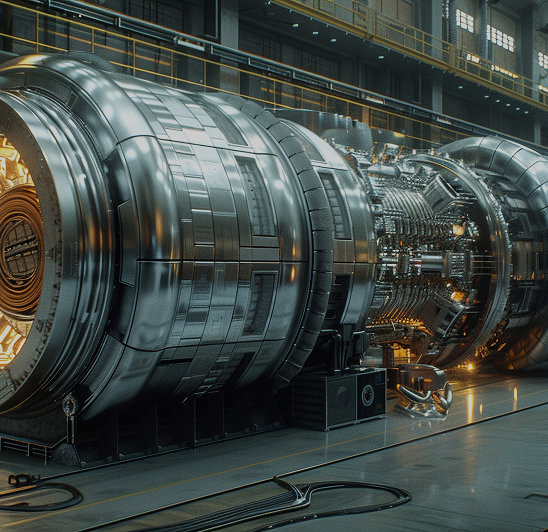

Energy & Power Generation

Whether you’re manufacturing turbines, cutting composite blades, or shaping insulators, our tools withstand extreme conditions and deliver clean results, contributing to more efficient energy production.

Electronics & Semiconductor

Our diamond tools are trusted for slicing, grinding, and polishing silicon wafers and ceramics used in semiconductors, circuit boards, and chipsets. Low vibration and high consistency make them ideal for precision electronics.

Composites & Ceramics

Machining advanced materials like fiberglass, carbon fiber, and technical ceramics requires tools with exceptional edge retention. CRQ tools minimize chipping and cracking while extending tool life and performance.

Rubber & Plastics

We provide tooling solutions that cut cleanly through thermoplastics, rubberized materials, and synthetic polymers without warping, fraying, or degrading surface quality.

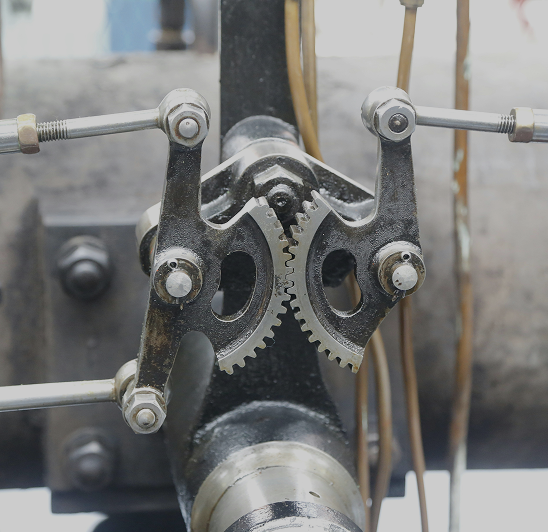

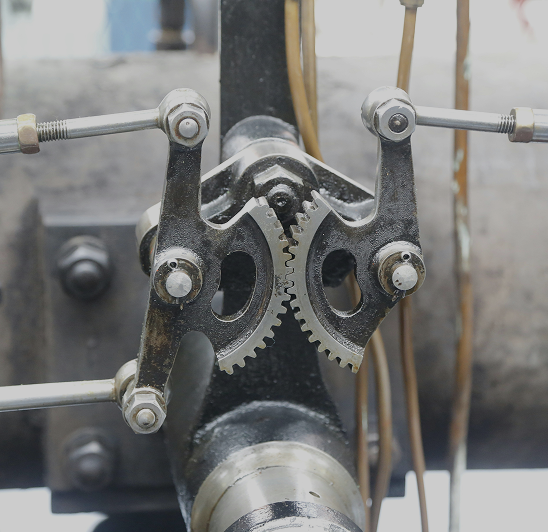

Automotive Industry

Used in machining engine parts, brake components, and hard alloys, our tools meet the demands of large-scale production with long wear life, fast cycle times, and unmatched surface finish quality.

Stone & Natural Materials

From granite to marble, our diamond tooling delivers clean cuts, reduced vibration, and longer tool life—ideal for architectural detailing, industrial shaping, and decorative applications.

Visual Insights into the Industries That Rely on Our Precision Tools

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality