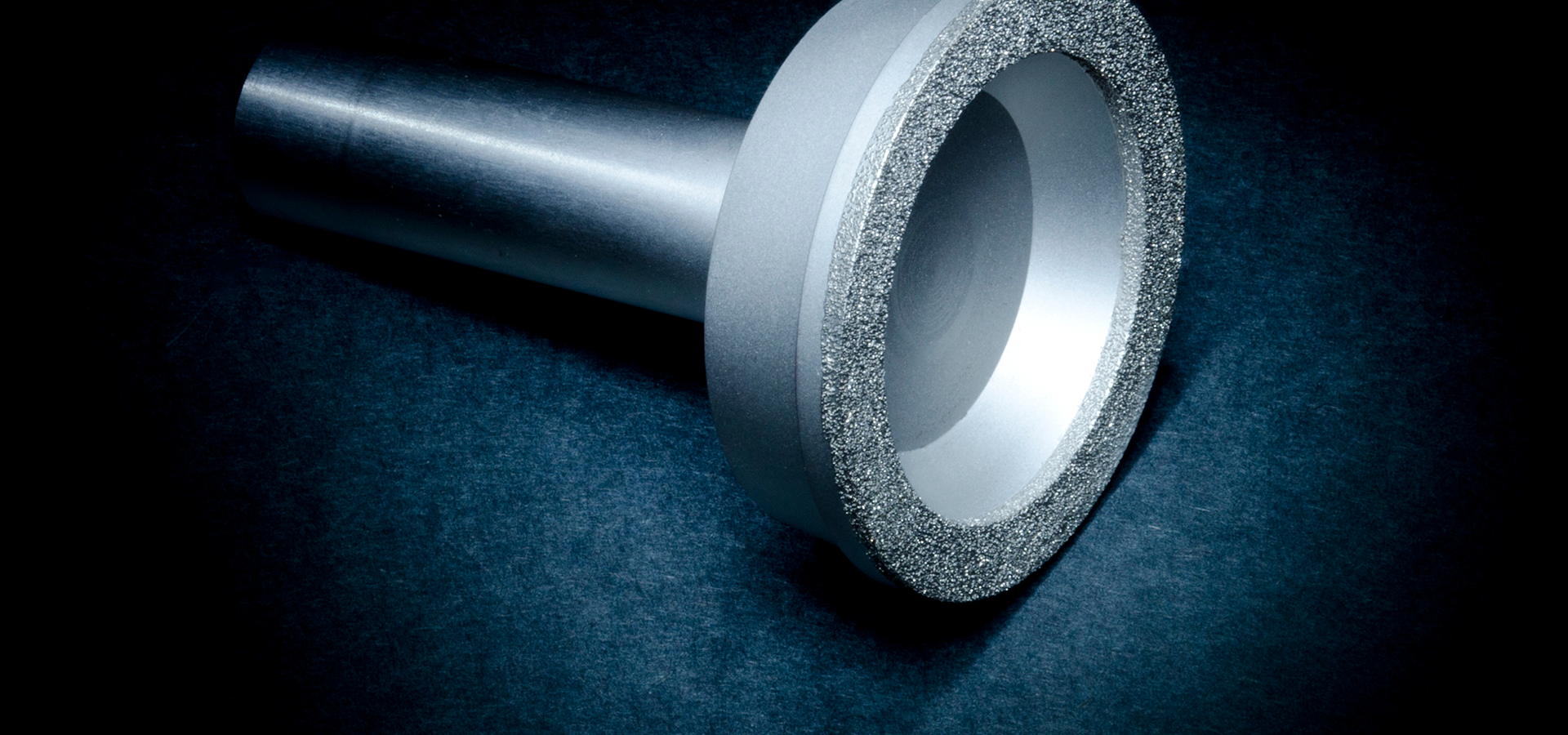

Grinding Wheels – Precision Diamond Grinding for Demanding Applications

CRQ Technology diamond grinding wheels are developed for high-performance material removal, edge refinement, and surface finishing across a wide range of hard and brittle materials. Designed for efficiency and consistency, they are ideal for applications where precision and durability are non-negotiable.

Request a custom solution

Have a specific application in mind? CRQ offers custom mandrels tailored to your operational needs. Contact us for consultation and quotes.

Engineered for Precision and Endurance

Applications

- Advanced ceramics and composites

- Hard metals (tungsten carbide, HSS, etc.)

- Semiconductor components

- Optical lenses and glass

- Tool and die making

Configurations & Variants

To meet varying technical requirements, our routers are available in multiple configurations:

- Bond Types:

- Shapes:

- Grit Sizes:

- Mounting Options:

- Resin, metal, vitrified, or hybrid bonds for different material interactions

- Straight, cup, dish, and custom geometries

- Ranging from coarse for rapid stock removal to ultra-fine for polishing

- Flanged, arbor hole, or custom

- Sizes:

- Resin, metal, vitrified, or hybrid bonds for different material interactions

- Bond Types:

- Straight, cup, dish, and custom geometries

- Shapes:

- Ranging from coarse for rapid stock removal to ultra-fine for polishing

- Mounts:

- Flanged, arbor hole, or custom

CRQ offers design-to-delivery support for custom router requirements. From tool profile design to application-specific performance optimization, our team ensures you get exactly what you need — no compromises.

Request a custom solution

Have a specific application in mind? CRQ offers custom mandrels tailored to your operational needs. Contact us for consultation and quotes.

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality