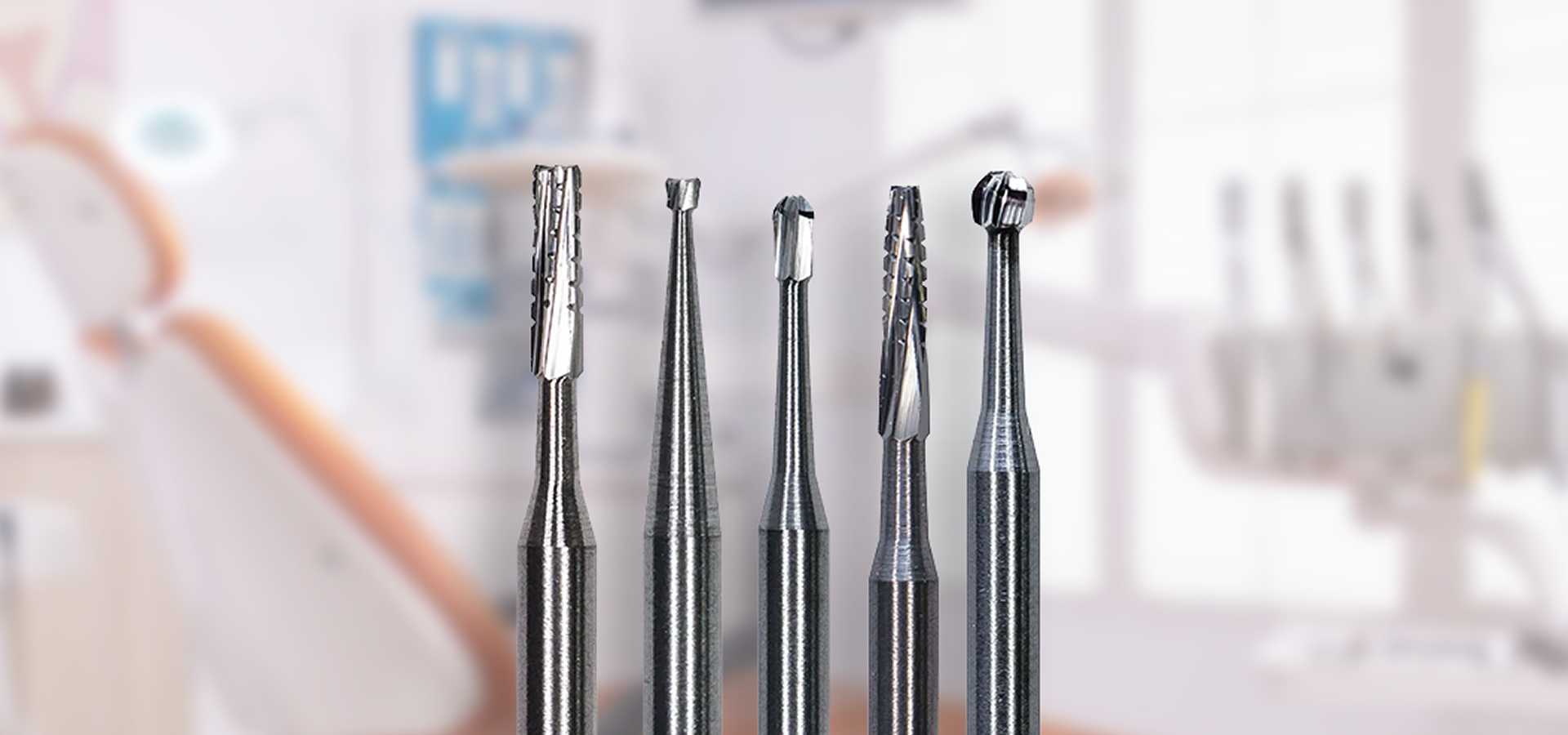

Mandrels – High-Precision Diamond Tools for Shaping, Grinding & Polishing

CRQ Technology diamond mandrels are micro-precision tools engineered for detailed shaping, grinding, and polishing tasks. These tools are essential in operations involving hard-to-machine materials such as ceramics, carbide, hard metals, and dental alloys.

Request a Custom Solution

Have a specific application in mind? CRQ offers custom mandrels tailored to your operational needs. Contact us for consultation and quotes.

Designed for Detail Work

Built with tight tolerances and superior diamond bonding, our mandrels excel in precision internal grinding, profiling, and polishing applications. Whether in industrial manufacturing or medical labs, they deliver stable, repeatable performance in even the smallest spaces.

Applications

- Internal grinding of dies, molds, and cavities

- Dental restoration shaping and polishing

- Deburring and micro-finishing of carbide tools

- Fine work on ceramics, glass, and hardened metals

Tooling Options

- Sizes:

- Available in micro and standard diameters

- Bond Types:

- Resin, metal, and hybrid options

- Shapes:

- Ball-nose, pointed, cylindrical, and custom profiles

- Mounts:

- Shank-based for handheld or CNC systems

- Sizes:

- Bond Types:

- Shapes:

- Mounts:

- Available in micro and standard diameters

- Resin, metal, and hybrid options

- Ball-nose, pointed, cylindrical, and custom profiles

- Shank-based for handheld or CNC systems

Key Benefits

- Ultra-precise material removal

- Minimal vibration, even at high RPMs

- Excellent surface finishes with minimal secondary processing

- Customizable profiles and sizes available

- Ideal for manual and automated workflows

Request a Custom Solution

Have a specific application in mind? CRQ offers custom mandrels tailored to your operational needs. Contact us for consultation and quotes.

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality

- CRQ

- Consistency | Reliability | Quality